For temperature measurements in fluids, 0.125” O.D. closed-end stainless steel temperature probe housings have long been a standard. However, with the growing demand for faster time response in microfluidic applications, that is changing. Industrial and environmental testing, pharmaceutical applications, the life sciences, drug discovery/screening, point-of-care applications and many other applications are demanding smaller, faster temperature probes. Not only is there a desired end to have faster test results but there is another “green” benefit. In some applications, smaller temperature probes mean that smaller vessels may be used which means a reduction in the use of some toxic reagents.

As an example of what kind of performance improvements design engineers can expect, North Star Sensors conducted a temperature response test in a precision-controlled temperature bath.

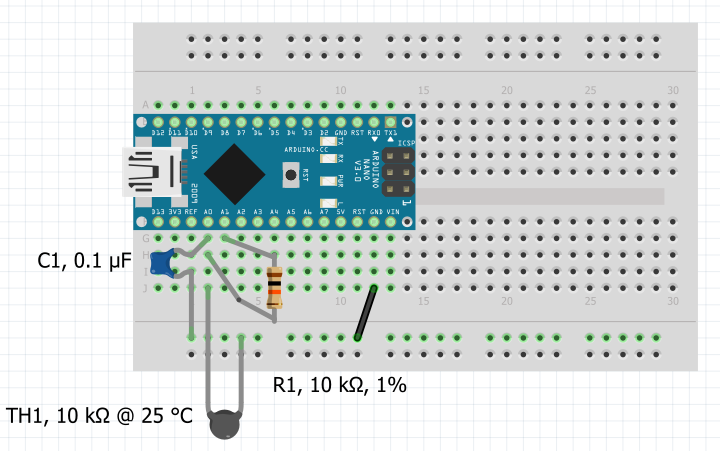

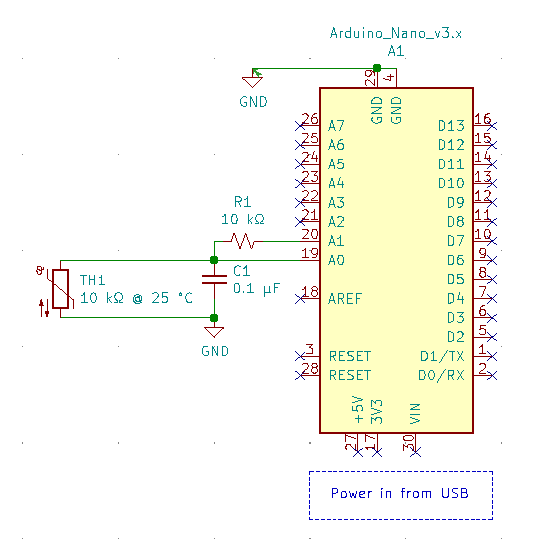

We built a measurement system that can record the temperature of 2 probes simultaneously at a rate close to 1500 measurements per second for each probe.

In the picture above you can see a commonly sized probe with an outer diameter of 0.125” and a micro probe with an outer diameter of 0.032” passing through a rubber stopper.

For this time response comparison test, the probes were allowed to equilibrate at room temperature and then were quickly inserted into a 70 °C temperature-controlled oil bath. The rubber stopper was used to ensure that the insertion depth into the bath was equal for both probes, and that they entered the bath at the same time.

The time constant of a thermistor is the time required to change 63.2% of the difference between an initial and final temperature. For this experiment, the starting temperature was about 22 °C and the final temperature is 70 °C. Using these numbers, the time response of the micro probe in this configuration was approximately 0.8 seconds, while the time response of the 0.125” O.D. probe was about 6.7 seconds. This is a significant performance increase. The micro probe has a diameter about 1/4 the size of the standard probe and has a time constant about 8 times faster.

For high performance applications where a small probe is desired, the North Star Sensors’ microprobe series really stands out with excellent sensitivity, accuracy, environmental protection, and time response.

Because each temperature application has unique characteristics, we strongly encourage our customers to contact us early in the design phase of their projects. This way, a variety of options may be discussed and the best balance between performance and price can be targeted.

Author: Tim Lavenuta